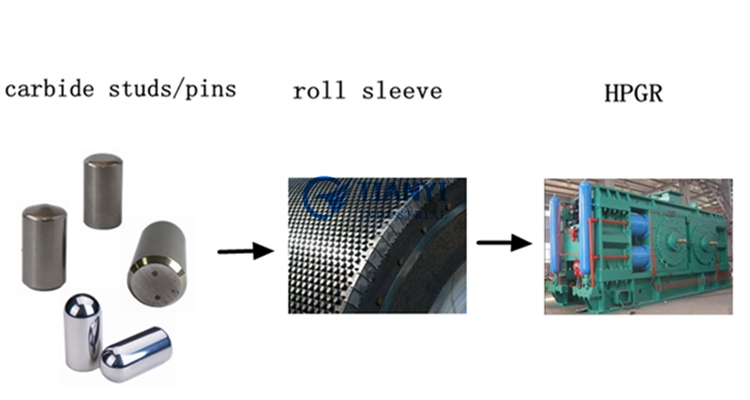

硬质合金柱钉在HPGR设备上的应用:

1.如何安装:

在辊压机钢件辊套上均匀分布安装孔,加工出柱钉孔,将硬质合金柱钉装配在钢件辊套上。柱钉与辊套孔采用间隙配合,用高强度胶粘合,硬质合金柱钉露出辊套表面5mm,提高工作面耐磨性能。

2.工作原理:

复合硬质合金柱钉的辊套,在高压状态下,主动辊,从动辊运转,实现物料破碎。

3.效果:

HPGR设备的使用效率高

设备使用寿命长

减少设备的检修停机时间

Application of tungsten carbide studs in

HPGR equipment:

1. Installation:

The tungsten carbide studs evenly

distribute installation holes on the steel roller sleeve of the roller press,

processing stud holes, and assemble the hard alloy studs on the steel roller

sleeve.

And the studs and the roll sleeve holes are in clearance fit and are bonded by

high-strength glue, and the hard alloy studs are expose out of the surface of

the roll sleeve for 5mm, so that the wear resistance of working face is

improved.

2. Working principle:

the roller sleeve of the composite hard alloy

stud rotates under high pressure, the driving roller and the driven roller

rotate to realize material crushing.

3. Effect:

(1) High use efficiency of HPGR equipment.

(2) Long service life of equipment and

reduction of maintenance downtime of equipment.

BACK